- +33 (0)3 84 56 16 62

Menu

-

MenuBack

- Home

-

Catalog

-

-

Applications

-

-

WATERPROOFING

Roofs, terraces or balconies waterproofing

CONCRETE INDUSTRY

Excess of concrete removing

ASBESTOS

Asbestos removing

-

INDUSTRY

Production facilities maintenance and cleaning

TILES AND FLOOR COVERINGS

Tile, carpet, lino and glue

ROUGHCAST REMOVAL

Renovation works

-

FRAMEWORK

Worm-eaten wood scraping

PUBLIC WORKS

Infrastructures: roads, bridges, etc..

LANDSCAPE GARDENING

Stump removing and excavation

-

-

-

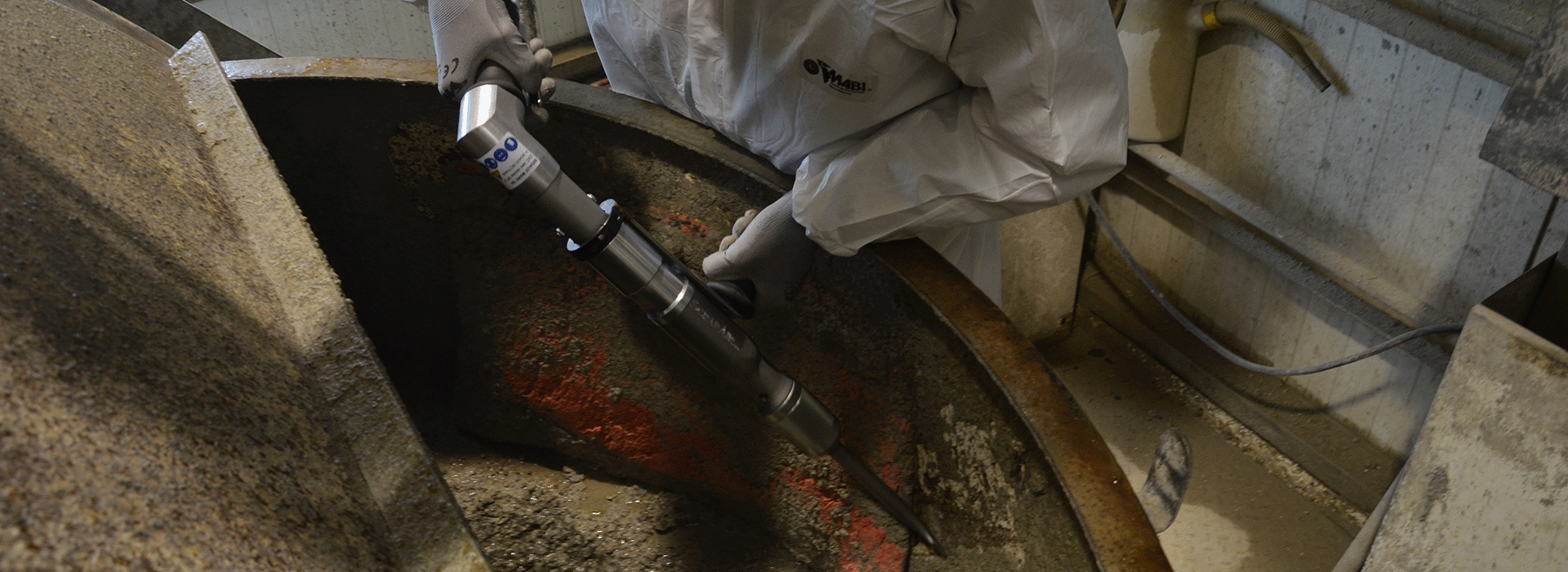

Pneumatic scalers

-

- Users

- Resellers

- Contact

- Advice & support: +33 (0)3 84 56 16 62

- info@mabi.fr

Menu

Menu

-

MenuBack

- Home

-

Catalog

-

-

Applications

-

-

WATERPROOFING

Roofs, terraces or balconies waterproofing

CONCRETE INDUSTRY

Excess of concrete removing

ASBESTOS

Asbestos removing

-

INDUSTRY

Production facilities maintenance and cleaning

TILES AND FLOOR COVERINGS

Tile, carpet, lino and glue

ROUGHCAST REMOVAL

Renovation works

-

FRAMEWORK

Worm-eaten wood scraping

PUBLIC WORKS

Infrastructures: roads, bridges, etc..

LANDSCAPE GARDENING

Stump removing and excavation

-

-

-

Pneumatic scalers

-

- Users

- Resellers

- Contact