STRIPPING WITH A NEEDLE HAMMER

With over 50 years’ experience in the stripping field, Mabi expand its pneumatic tools range for professionals with the needle hammer. Desirous to offer a global solution to its customers, the needle hammer completes perfectly the ergonomic stripper Scrap’air range offering the power of needles.

Painting, rust, calamine residues stripping on small and midsize fragile surfaces will become easier minimizing the impacts on the base.

All the robustness and the power of the ergonomic Mabi tools have been concentrate in this needle hammer to secure a safe and efficient stripping.

Save time with the needle hammer

The needle pneumatic hammer, also called needle scaler, has for first vocation the rust removal. This friable and rough material develops on ferrous materials because of air and humidity. It is an iron oxide that fragilize the attacked objects in a phenomenon, also called, corrosion phenomena.

Rust progresses fast and can fragilize structures or significantly damage the material it is attacking. Sanding or using chemical products to remove rust are solutions for small surfaces and without any deadline. As professional, deadlines are often more important than budget and that’s the reason why Mabi decided to develop a powerful needle hammer answering to professionals’ requirements.

In order to remove rust without damaging the healthy substrates, needle hammers ensure the fall down of the friable parts only thank to the dispatch of the force on the 18 needles.

The industry sector has also found several applications for this pneumatic needle hammer. It becomes a tool for the finishing touches stripping all kind of residues such as painting, resins, …

Industrial foundries adopted also the needle scaler for the deburring operations which is a very important step in the production process of this industry.

Save time and give a neat appearance to your work thank to the needle hammer Mabi.

A needle hammer, how does it work?

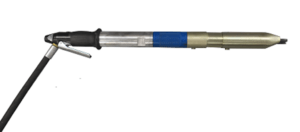

A needle hammer is a distant cousin from the ergonomic stripper Scrap’air and is built in 3 parts:

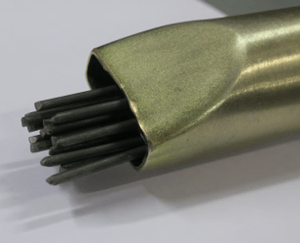

– the head of the machine including the needles,

– the handle (personalize length is possible),

– the grip.

The working principle is almost the same as the one on the ergonomic stripper Scrap’air. The difference is that the impact force is spread of the 18 needles and not only on the chisel or knife. The impact generated by the piston vibrate the needles and gently strip the rust material. The pieces of rust are detached and fall from the substrate down. The needles are fixed close one to each other to concentrate the action of the machine and ensure the stripping of the rust without touching to the healthy parts.

The needles hammer Mabi benefit from the ergonomic grip from Scrap’air v1 range for an optimal take in charge during work.

The length (64cm) is perfect to stay at a comfortable distance being protected from the chips during work and able also a good visibility on the stripping work.

Industrials, professionals from the shipbuilding branches, contact us to try the needle hammer Mabi!