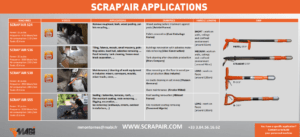

SCRAP’AIR APPLICATIONS

One of the principal values from Mabi company is the innovation. It is based on this vocation, that founder Marc Bidaux developed his first products. At this time, he was working as applicator for the wood frame treatment against xylophagous insects. Those daily repetitive actions, wood stripping before treatment, spay of chemicals products, sometimes in risky situations (height of the wood frames, cramped corner,…) have motivated him to create adapted and safe tools that would help in those tasks.

It is in this way that the first injectors arrived on the market on 1969 to secure a good spread the in the woods. Thank to this injection system, operator limit the contact with the chemicals products, and he can also proceed to a second injection months or years after. (www.mabi.fr)

Further to this first improvement, Marc Bidaux decided to find a solution for the wood preparation. Stripping the frames by hand is a long and fastidious task but it is a necessarily step to ensure the success of wood treatment. From his thinking and studies came out Scrap’air range in the beginning of the 80: an ergonomic pneumatic striper with a sharped knife for a fast wood stripping. Thank to pneumatic energy, the machine convinced by its lightness and its handling. Shortly demands for other applications in addition to wood stripping were there. Mister Bidaux patented his ergonomic pneumatic stripper and developed the range to propose now a days four powers.

SCRAP’AIR: CHANGE YOUR VISION OF STRIPPING

There is now a days several energy sources for hand tools. (see article “THE ADVANTAGES OF PNEUTAMIC TOOLS”). Generally, the power of the electric and hydraulic tools is given in kw/h.

Pneumatic equipment has another unit of measure, which is the joules. The ergonomic stripper Scrap’air range has 4 different powers: 15, 25, 30 & 35 joules that fit perfectly for lots of diverse applications on several underlayers.

The different ergonomic grips equipped with antivibration systems and the different lengths, will allow the users to benefit from adapted tools to their work conditions and environment.

The tools range has been developed to give more versatility to the ergonomic stripper Scrap’air to answer to various applications (see our article about the tools for Scrap’air range).

Now a days, Mabi sells its equipment to professionals in the building renovation for treatment of wood frames, waterproofing removal but also to the industry for industrial maintenance, deburring, silos, etc. ….

Discover hereunder part of the ergonomic stripper Scrap’air applications organized according to their impact force. A click on the YouTube icon will open the video from the Scrap’air model.

You have used Scrap’air in another field or for another work,

You would like to use Scrap’air for other applications,