Stripping the London Underground trains Pneumatic hammer Scrap’air is now used for the renovation of the London Underground trains. More info in hereunder article.

London underground: a bit of history.

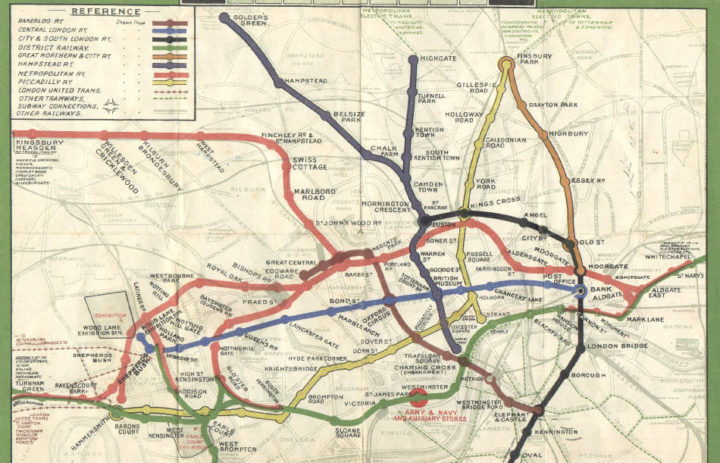

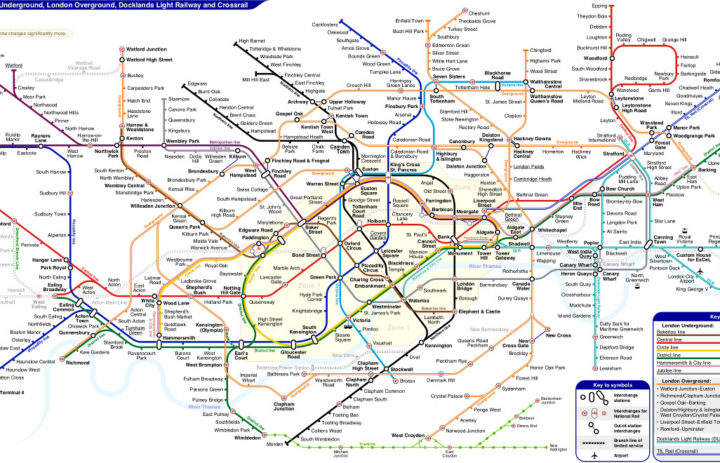

Always called “The tube”, London underground is a mytic construction. It was the first underground designed by Charles Pearson and unveiled in 1863. At the beginnings, it was composed by 6.5km ways, now a days, it total more than 400 km on 11 lines. It is easily identifiable thank the iconic logo with the red and blue roundel and the stylized map.

Trains maintenance: a major challenge.

To answer to growing travelers needs and to follow the railway network development, more and more trains were put into circulation. Maintenance (from the trains and network) becomes a major challenge for the Tube managers. The renovation from the hundred trains in circulation allows huge savings.

The initial cost is high so thank the renovation; lifetime from the trains is extended over the years. Whether it concerned the renovation of seats, floor covering or a complete train, it’s essential to optimize the time of immobilization of the carriages. Equipment becomes very important to secure the efficiency of the renovation.

Scrap’air eases the removal of floors covering.

Until now, this operation was done without any particular tool. Powerful machines are required to remove the resistant covering (like vinyl or PVC) that in the same time, protect the users health. With Scrap’air, it’s possible!

The power of pneumatic Scrap’air reach a strike force adapted to vinyl floors covering without damaging the under surface. The high frequency of our pneumatic hammers secures a maximum performance. By adding the double anti-vibration system, technicians are protected against vibrations during all their work. The different available length permit to the users to adapt their work position. Benefits are several : performance improvement, time saving and work position respected.

In this precise case of London underground, technical workers use Scrap’air 36 to remove the floor covering: 50cm long for less than 3.5kg, the size of the S36 short is perfect for an intensive use during all the day. The S36 long is ideal for a standing work position.

Have a look on the power of 25 joules and 3500 blows/min: