The benefits of Scrap’air in the asbestos removal sector.

Nowadays it is well known that asbestos is carcinogenic, yet it is still present in many workplaces in France and Europe. But do you really know what asbestos is? where it comes from?

What is Asbestos and why was it used?

Asbestos comprises of naturally occurring silicate minerals with a fibrous texture and was widely utilized in the industry for its resistance to heat, fire and chemicals while being an excellent electrical insulator and sound absorber. Due to these beneficial properties it was used for many years in the construction industry until Scientists found that Asbestos is extremely dangerous to health. Its use is now prohibited and legislation to remove it has been implemented.

How is Asbestos Removed?

Due to its particularly dangerous nature Asbestos Removal sites are subject to strict regulation and supervision. To protect workers health and limit risk, special training has been developed. Only operatives who have received the specific training are allowed to carry out decontamination work and handle the disposal of the contaminated waste.

What safety measures should be put in place?

Asbestos was widely used in many materials such as paints, coatings, glues and bitumen in order to improve their performance, it is therefore still widely found in many buildings and requires removal.

Before the removal of Asbestos, job sites must be set up to protect operators and the surrounding environment. A decontamination chamber will be erected before and after entering the contaminated area. Additionally, operatives will wear special PPE including disposable gloves and suits while to protect them from breathing the harmful Asbestos dust particles they will wear a high specification respirator.

What are the requirements for tools and equipment?

Due to the measures to protect the operators, any tools and machines used to remove the contaminated material must be kept contained within the work site. They cannot be taken in and out of the site easily due to the risk of contamination. Therefore, it is very important that any tools and machines selected for the job are chosen for their robustness and features that make them suitable for this challenging application and environment.

After use in such environments tools and equipment must be thoroughly decontaminated using water and special chemicals, many typical tools will not be suitable for such harsh treatment.

How Scrap’air can help

Due to the highlighted restrictions and the specialist nature of working in Asbestos abatement there is a reduced supply of suitable equipment that is up to the task.

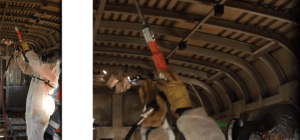

The specially developed Scrap’air pneumatic range of ergonomic strippers are especially well suited to such extreme environments.

Investing in a Scrap’air tool means:

- Enhanced ergonomics meaning a lightweight and compact tool making the job of removal easier and faster

- A tool which will last, reliable, easy to decontaminate & maintain.

- Efficient and powerful pneumatic power for continuous and productive performance.

- Full support and delivery direct to your work site.

An extensive range of available grips and lengths makes the Scrap’air line of strippers the perfect solution to answer your worksite demands for the safe removal of Asbestos containing materials.

You are a Asbestos removal specialist?

You have a special project or application requirement?

Share with us your experience!!